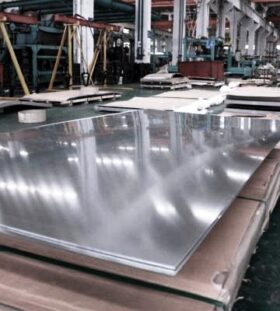

Some Industries That Make Use Of Stainless Steel Sheets

Alloys of metals use a mix of chemicals to improve the physical and chemical properties of the metal. Stainless steel is an alloy of iron, and it has additional elements like chromium and nickel in it. Adding chromium and nickel protects the alloy from harmful chemical changes that result in corrosion. Over time, stainless steel has been used in multiple industries like surgical instruments, cutlery, construction of buildings, constructing of railway lines, etc.

Multiple Industries Make Use Of The Useful Properties Of Stainless Steel Sheets

These industries are as follows-

Used In The Construction Sector

Stainless steel sheets are highly flexible and can be cut and slit per the user’s needs. This flexibility increases the demand for stainless steel sheets in the construction sector, where it is used as a cladding material for both the interior and the exterior of a house. Cladding uses a die-casting process to press one material over the other.

Stainless steel cladding on the exterior of a house gives a distinctive architectural style to the building. Moreover, with the latest technology, stainless steel sheets need not be only silver; you can even get colored sheets to add extra appeal to the exteriors of your house. A stainless steel sheet supplier will be able to show you a whole range of cuts and colors as per your particular demands.

The chromium keeps the external walls free of oxidative damage. Moreover, the external cladding of stainless steel makes the outer surface highly cleanable. In fact, cleaning stainless steel is more manageable than cleaning aluminum and copper.

Stainless steel sheets are used as a cladding material for the interiors of the house, like the kitchen and bathroom walls. The kitchen walls have to tolerate high temperatures, and stainless steel is resistant to heat.

Likewise, the bathroom walls get wet quite often, and stainless steel protects them against moisture. The presence of chromium, nickel, and molybdenum in the stainless steel forms a non-porous layer on top of stainless steel that prevents further damage even when exposed to moisture.

Manufacturing Kitchen Equipment

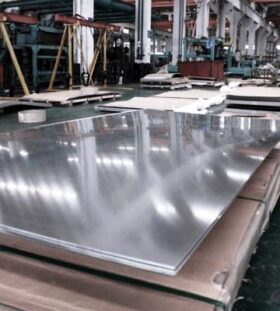

Stainless steel sheets are used to coat kitchen equipment. The covering protects the equipment against oxidative damage, and it makes them scratch-resistant and highly durable. The high durability lowers the maintenance cost of the equipment.

Stainless steel sheets can be expensive as many elements are added to them to improve their properties. So, constructing the entire equipment out of stainless steel may not be economically feasible. Usually, the main body is made of a material like carbon steel, and the outer covering is that of a stainless steel sheet. This makes the equipment cost-effective and improves the properties at the same time.

The Manufacturing Of Surgical Instruments

Stainless steel sheets are the material of choice for making surgical instruments like forceps, needles, surgical blades and knives. Surgical instruments need to be clean and free of microorganisms and corrosion. Even the slightest chance of bacterial infection after surgery can be fatal as it causes septic shock. Hence, surgeons take special care to ensure that their hands, the surgical instruments and the operation theater are absolutely spic and span.

Corroded surfaces are notorious for harboring those bacteria that grow in the absence of oxygen. Bacteria that are responsible for causing tetanus are bacterial species that survive in the absence of oxygen. And this species survives in corroded surfaces because they create an oxygen-free environment by scavenging on the ambient oxygen to make iron oxide which is the major component of rust.

The presence of metals like chromium and nickel makes stainless steel rust-free, and this is a great advantage from the point of view of the manufacturers of surgical instruments.

Many surgical instruments also have springs attached to them. A common surgical instrument that uses a spring is a surgical stapler that is used to close the cut after the surgery is over. Stainless steel sheets are used to manufacture the springs that are used in surgical instruments like staplers.

For a surgical stapler to work optimally, it is vital that the spring is not corroded. A corroded spring will not create an impact that is strong enough to close the surgical cut precisely.

Another reason why stainless steel sheets are used for manufacturing surgical instruments is their ability to withstand very high temperatures. Stainless steel can tolerate temperatures as high as three hundred degree Celsius. So stainless steel will be able to tolerate the heat-based sterilization process to kill off the germs on the instrument.

Construction Of Pressure Vessels

Pressure vessels are used to store fluid at a pressure level that is different from the ambient pressure. LNG, or liquified natural gas, is carried in pressurized containers. Likewise, the gas carried by deep sea divers or firefighters and the boilers in a thermal power plant is also contained in a pressurized vessel.

Stainless steel sheets are also used in manufacturing pressurized vessels because of their mechanical strength. Stainless steel is strong and can resist a lot of wear and tear, so it is often used to line pressure vessels that need to withstand pressure as high as two hundred bars.

Used For Treating Dental Problems

Stainless steel sheets are used for manufacturing dental crowns. They may not look very appealing because it covers the teeth in a metal-like appearance, yet they are regularly used by dentists.

Stainless steel sheets are the preferred choice because they are durable and they are cost-effective. Also, they make the treatment easier because they do not require much scaling. The damaged tooth needed to be scaled a little before the crown was fitted onto it. With stainless steel crowns, not much scaling is required. This eliminates the risk of overexposure to dental pain and associated complications.

Conclusion

Stainless steel sheets have gained widespread popularity across various industries because of their desirable properties. The sheer mechanical strength and great aesthetic have made it irreplaceable across sectors. Adding elements like nickel, molybdenum, chromium, and nitrogen, in some cases, makes it resistant to corrosion, highly durable, and easy to clean and fabricate.